Well, it has been a long time since I last posted and I would like to catch up. Thankfully, business has been good and I have had little downtime. Here is a 2004 Kia Optima with a 2.4 liter 4cylinder motor. I see a ton of Hyundai/Kia vehicles in my area. They are very popular. The shops concern is the vehicle seems to run pretty decent with a slight lack of power but once warmed up has a very shaky idle. There no codes. I first look at some fuel trims which seem to be acceptable. I road test the vehicle and no doubt it is slightly underpowered and indeed has a shaky idle. I decide to look at engine vacuum to start with because the vehicle feels like the EGR valve is stuck on at an idle.

As you can see 14" of vacuum at an idle. I normally see these vehicles produce 19" of vacuum on a good running vehicle. The low vacuum is a clue. The next thing I do is feel the EGR valve with the vehicle running. It feels pretty cool the touch. Now, this is not an absolute foolproof diagnostic test. However, typically if an EGR valve is flowing some exhaust gases it will be warm to hot to the touch at an idle. Warning, do yourself a favor hit the EGR with a non contact laser thermometer first before putting your hand on it. Ok, EGR not flowing at an idle, what is next?

I like to scope things. I feel it gives me the best bang for the buck. In my business remember I need to be fast and efficient. I want to look at crankshaft sensor to camshaft sensor patterns and how they correalate to each other. If you notice the cam sensor is driven off the exhaust camshaft of this car.

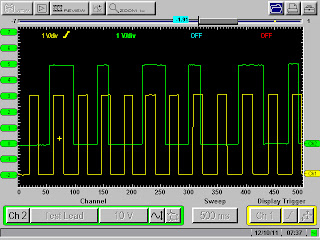

Here is the CKP sensor pattern in yellow on channel 1 and the CMP sensor pattern on channel 2 in green. Call it my OCD or whatever I typically always use channel 1 for CKP sensors, it keeps captures consistent. Ok, is this a good pattern? This is where data acquisition comes into play. So I pull up a known good waveform from my library.

Here again CKP is channel 1 in yellow and CMP is channel 2 in green. What I can see immediately is that the Cam sensor pattern either intersects the Crank sensor pattern halfway or straddles it midway. Lets revisit the vehicles waveform at a different timebase.

It is shifted no doubt. Be careful using this method. The pitfall is that the Cam sensor is only on one camshaft. So we could have a situation where one camshaft that drives a sensor is in time and the other that has no sensor is off. When presented with that situation I use running compression with a pressure transducer and look at exhaust and intake valve opening events. Here, I didn't have to. I advised the shop to check timing belt alignment. Sure enough they called me back later that day after resetting the timing belt. The vehicle performed and idled well.

I recently was at a shop that just did a timing belt replacement on a 2004 Hyundai XG350 3.5 liter v6 with 75,136 miles as part of routine maintenance. The vehicle ran well into the bay. Unfortunately, it ran quite poorly after the service. It was setting misfire codes and had a terrible lack of power and a rough idle. These cars normally idle like glass and perform quite well.

The tech that did this job was sickened. He is a very thorough tech and I have been there a couple of times in my life where the vehicle ran worse after I serviced it. It is a bad feeling. I really felt for him. I went over the timing belt procedure with the tech and on the car several times. I often find that more can be found out asking questions than looking at the car. After some head scratching the tech said something that stuck with me. He said he had a hard time seperating the crank pulley from the crank sprocket. With this I broke out the scope and decided to check CKP/CMP correalation. I had a hunch.

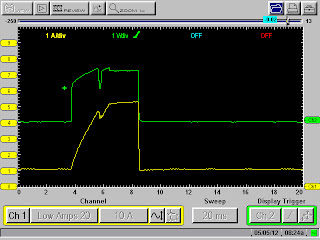

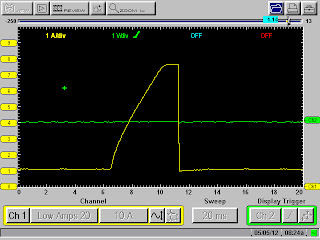

Here again CKP in yellow and CMP in green. I didn't have a known good pattern handy. But, I felt very confident that it would follow suit like the Kia previously. Here, is another shot.

Cursor 1 is where the rising edge of the CMP sensor is and cursor 2 is where it should be. I know what happened. I tell the tech to get the timing belt off and remove the crank sprocket and CKP interruptor ring behind the crank sprocket.

Here is the interruptor. Those blades pass through the CKP sensor causing the square wave pattern. If you notice there are two dimples on the ring that should not be there.

Here is the backside of the crank sprocket. The two protrusion tabs that should go into the holes on the CKP interruptor ring are worn off.

Here is how it fits together. What happened here is when the tech was seperating the crank pulley from the sprocket it pulled the crank sprocket forward and disengaged the CKP interruptor ring from the crank sprocket. When the tech reinstalled everything it moved and therefore corrupted CKP/CMP timing. This caused the vehicle to run like the timing was retarded drastically. This was very easy to do. Hyundai does not extend the crankshaft woodruff key all the way in and relies on these two small tabs that are easily broken to index everything. One new crank sprocket and interruptor ring and away it went.

This blog will explore the world of automotive diagnostics. We will show a new case study every week.I will also offer my opinions on various issues in the automotive world.

Sunday, October 28, 2012

Tuesday, June 5, 2012

2001 Nissan Pathfinder

Here is one 2001 Nissan Pathfinder with 141,893 miles on it that is due for state inspection. The dilemma is the vehicle has the dreaded P1320 code for primary ignition. This is a very common code on Nissan vehicles with COP (coil on plug) ignition. There are three items that I see that will cause this code. One is bad COP units (more on this later), wrong spark plugs, and someone has tied the rpm input for a remote start into one of the COP units. The shop owner asked me to look at this because the customer cannot go for 6 new COP units. He needs a definitive answer on how many COP units are bad and if other issues are at hand. The code set criteria for this code is a little misleading. Basically, it says that there is a missing primary signal. So, this vehicle should be missing, right? Well, this vehicle runs well with no apparent misfires. Time to pull a wiring diagram.

Out comes the low amp probe. I make jumpers for both contacts of the ECM relay and I am going to trigger off of #1 COP control circuit.

You don't have to be a scope jockey to see that two amperage patterns are different from the rest. The yellow trace is the coil amperage and the green is the #1 trigger. Forgive my forgetting to zero my probe. Let's add the firing order which is 1-2-3-4-5-6.

As you can see cylinder #1 is lower than the rest and cylinder #4 is higher. These are our two odd men out. Even the pattern at this timebase is not the same as the other four COP units. A good healthy COP unit on this application is typically 6-8 amps. Number 1 is at 4 amps and number 4 is at 9 amps plus. Lets look at these two and a healthy one closer at a better timebase.

Here is number one. Looks to me that there is an issue with this COP unit that is also affecting the trigger. More evidence to condemn the COP unit. Let's look at number four.

A couple things become apparent here. The amperage is high and the ramp is rather straight. Not, what I typically see. Let's look at a good cylinder.

Now, that is a typical Nissan COP waveform. Notice the ramp pattern and amperage. Again, forgive me for not zeroing my probe.

So here we are twenty minutes later and we have a definitive answer for the shop owner. I advised him that cylinders #1 and #4 COP units are the reason for the P1320. I also advise him to check the plugs while he is there. At this point I also tell him do not be suprised if these COP units at #1 and #4 have been changed and are aftermarket units. Sure enough the shop owner calls me the next day and tells me both units were recently changed with aftermarket units. He installed OE units, checked the plugs for proper brand and gap, and test drove the car. He was able to run and satisfy all the monitors for inspection and both he and vehicle owner were very happy. The MIL was out and a sticker was issued. At this point here goes my rant. The aftermarket in it's ongoing quest to provide "cheap" parts has shot itself in the foot. I see this time and time again. Quality doesn't cost it pays. The extra coin for an OE part is money well spent. Here is a prime example.

Sunday, April 22, 2012

A quick update

Sorry, I haven't posted in about a month. Fortunately, I have been really busy. Business has been good and I also have been doing some training at a couple of shops. I have been picking up quite a few new shops as well. I am fortunate enough to have networked with some really good people both in and out of the industry. You can never have too many good people supporting you. The best form of advertising in this business is definitely word of mouth. This is why I give free advice. Many times I will get a shop call me and ask me for an opinion or information. I may not get a job from that shop right away. But, usually I get something from them eventually. They remember I was helpful and knowledgeable and tell other shops.

I should have some more case studies posted soon. I have some more catalytic converter codes, misfires using the low amp probe, some GM electronic throttle control, some reprogramming, an arsenal update, and a one year Ottotest evaluation. Stay tuned. Of course, anything you want to see-email me.

I should have some more case studies posted soon. I have some more catalytic converter codes, misfires using the low amp probe, some GM electronic throttle control, some reprogramming, an arsenal update, and a one year Ottotest evaluation. Stay tuned. Of course, anything you want to see-email me.

Sunday, March 18, 2012

2002 Ford F-150

Here we have a 2002 Ford F-150 truck with a 5.4 liter engine and 121,306 miles on the odometer. The customers complaint is an intermittent extended crank especially first start. There is no history on the truck so I do not know if it has well taken care of or not. On a hunch I decided to hook up a fuel pressure gauge and crank the engine over.

This is what greets me. No fuel pressure. I quickly check for spark, injector pulse, and scantool communication. I have everything except for fuel pressure. Now it is time to figure out why. I do not want to disturb anything like connections or relays. So, I head for the inertia switch in the right side kick panel. With that exposed I can use my low amp probe to check the health of the fuel pump circuit and the fuel pump itself.

So, with everything hooked up I crank the engine over and take a snapshot of the scope pattern. The advantages of the low amp probe are many. I like it because it is quick and non-intrusive. Lets look at that pattern.

I get a non modulating 18 amp pattern. This is typical of a fuel pump that is locked up. High amperage with no humps. One thing I can take from this pattern is the circuit is in good shape or else we wouldn't be able to support almost 18 amps of current. Now, there is a caveat here. Be sure to inspect the wiring around the top of the tank and framerail before fingering the pump. So what can we do to also confirm our findings?

We go low tech! A quick wrap on the tank with a rubber mallet is usually enough to vibrate the pump enough to unlock. So I smack and retry. Here is the scopeshot.

Now that is ugly! A couple of more whacks and I get this.

The truck roars to life and this fuel pump sounds like a jet engine. Lets check our running pattern.

Amperage is a bit high at 8 amps peak. I usually see 6 amps or so. The pattern is terrible. This pump has seen better days for sure. I wouldn't be taking this truck too far. I report my findings to the shop owner. He calls the customer and explains the issue and gives an estimate. Customer refuses the job. Oh well, I hope he is handy with a rubber mallet. Here is an example of a good fuel pump pattern for comparison.

The low amp probe saved me so much time here. It is a great tool to utilize. It tells me more about a circuit and component than any other tool in my opinion. I often see low amp probes in the shops I visit. I always ask if they are using it. I usually get-"Nah" as my answer. Techs break out your amp probes and use them.

This is what greets me. No fuel pressure. I quickly check for spark, injector pulse, and scantool communication. I have everything except for fuel pressure. Now it is time to figure out why. I do not want to disturb anything like connections or relays. So, I head for the inertia switch in the right side kick panel. With that exposed I can use my low amp probe to check the health of the fuel pump circuit and the fuel pump itself.

So, with everything hooked up I crank the engine over and take a snapshot of the scope pattern. The advantages of the low amp probe are many. I like it because it is quick and non-intrusive. Lets look at that pattern.

I get a non modulating 18 amp pattern. This is typical of a fuel pump that is locked up. High amperage with no humps. One thing I can take from this pattern is the circuit is in good shape or else we wouldn't be able to support almost 18 amps of current. Now, there is a caveat here. Be sure to inspect the wiring around the top of the tank and framerail before fingering the pump. So what can we do to also confirm our findings?

We go low tech! A quick wrap on the tank with a rubber mallet is usually enough to vibrate the pump enough to unlock. So I smack and retry. Here is the scopeshot.

Now that is ugly! A couple of more whacks and I get this.

The truck roars to life and this fuel pump sounds like a jet engine. Lets check our running pattern.

Amperage is a bit high at 8 amps peak. I usually see 6 amps or so. The pattern is terrible. This pump has seen better days for sure. I wouldn't be taking this truck too far. I report my findings to the shop owner. He calls the customer and explains the issue and gives an estimate. Customer refuses the job. Oh well, I hope he is handy with a rubber mallet. Here is an example of a good fuel pump pattern for comparison.

Friday, March 9, 2012

Connections

In my travels I do a fair amount of straight up electrical work. I see my share of shorts, drains, and inoperative components at shops. I have always liked electrical work and it something for the most part shops tend to shy away from. Usually, tracing a short or getting into a battery drain is not as profitable as a brake job and can take up a lot of the techs/shops time. In todays vehicles there are literally hundereds of connections strewn throughout the vehicle. I wanted to share with you a couple I have encountered recently with a common theme-bad connections.

First up is a 2007 Cadillac Escalade EXT with climate control seat issues. This vehicle has both heated and cooled front seating with a mini blower motor for each seat. This is all controlled by the CCSM (Climate Control Seating Module) under the passenger front seat. I first became involved with this when the shop called asking me if I could program a new CCSM they were going to install in this vehicle for the problem of no operation of climate controlled seating. The dealer told the shop it needed to be programmed. Most GM modules do need to be programmed. A quick check of service information revealed this did not need programming it was "plug and play". I advised the shop of this and they installed the new CCSM and still had no climate control seat operation. That is where I came in. I first verified proper inputs to the CCSM with my Tech2 and also backprobed powers and grounds at the CCSM. All were good. Why wasn't it working?

Let's disconnect the connector and check for pin deformation, etc.

Well here we go. The main power feed terminal for the CCSM is smoked. I checked resistances of the seat heaters and blower motors from the disconnected connector. All were in specifications. I then amp drawed the circuits to check them dynamically and again all were good. A lot of current under the best of circumstances goes through this terminal. Better to be safe than sorry. A call to the dealer revealed they had this pigtail in stock-no suprise there, huh? A new pigtail was installed and we can now keep our butt warm in the winter and cool in the summer. How did we ever do without this?

Next up is a 2003 Toyota Sequoia that the battery would go dead overnight intermittently. The customer swears the headlamps turn on by themselves causing this. The shop has already installed a brand new battery and has never seen this phantom headlamp issue. I get called in and for the first couple of minutes of me manipulating switches and harnesses nothing happens. I turn my head and then look back and the headlamps are on and the switch is off and I have the keys in my hand. A second look and actually the DRL (Daytime Running Lamps) are on. DRL operation is controlled by the Body ECU. I hook up my Toyota Techstream scantool and I see no reason the Body ECU should be putting on the DRL lamps. I try to toggle the DRL relay on and off through the bi-directional functions of the scanner and they just stay on. Could the Body ECU be bad. Well, it is easy enough to disconnect. I do so and the lamps stay on. Do I have a stuck DRL relay? I don't think so since the vehicle should not have had the DRL lamps on to begin with key off. Hmm. Whenever I see phantom issues like this I think of two things-resistive shorts caused by moisture intrusion or bad grounds backfeeding. A quick voltage drop of ground circuits reveals excellent grounds. I am going for the resistive short. I start wiggling connections at the inerior fusebox which also serves as a junction box for many circuits including the DRL's and the lamps flicker. I trace the circuit to a particular connector at the fusebox. I cannot get this connector out of the fusebox. I have pliers on it and I do not want to break it off. I pull an adjacent connector at the fusebox and there are signs of moisture. There is green corrosion all over. I tell the shop owner he needs a fusebox. We finally get the connections out-here is the fusebox.

Taken on some water here for sure. A tech in the shop told me that this vehicle sees a decent amount of beach time in the summer months. Maybe, he got caught in the waves one time. Or, perhaps an old windshield leak. Here is another shot.

The moisture migrated into the fusebox and caused circuits internal to have continuity when they should not have. At first the shop owner asked me if we could save this fusebox. Not a chance!

This next one is from a body shop I service. It is a 2001 Ford Windstar with no rear lighting. Front lighting is operative. This vehicle uses a REM (Rear Electronics Module) to control the rear lighting. It is nestled over in the right rear of the vehicle behind a trim panel-see below.

I hook up my scantool to make sure it is communicating and getting proper inputs and to test the outputs. It is communicating and getting proper inputs. When I try to do output tests for the relays that control rear lighting via the REM-I hear nothing. A look at the diagram tells me that the relay command wire goes straight from the REM to the junction box under the left side of the dash. There are no connectors in between! So no divide and conquer mentality can be used here. To make matters worse the interior of this vehicle is fully intact. Usually, when I get a call from a body shop the interior is torn apart which makes it easier for me. This harness goes across the interior of the vehicle. So, I am thinking is a harness chafed on a seat anchor or rotted right in the middle of the truck. The nightmare scenario of taking this Windstar apart is gnawing at me. I know that the connections at the REM look good. I jump out the relay at the junction box and the rear lighting comes to life. So I know there is an issue at the control for the relay. Let's head for the junction box connector on the back that has the control circuit wire.

Well lookey here. I knew something was up when the connector was a bit of a pain to get out. Yes, water intrusion and Yes there should be four terminals on the top row and four terminals on the bottom. See what is missing?

There is the missing pin welded into the female terminal of the connector. This Windstar I believe has a windshield leak that started this ball rolling.

Finally, we have another fine GM vehicle. A 2006 Cadillac Escalade with complaints of no rear wiper and no rear defroster operation. I hooked up my Tech2 expecting to see a LGM (Liftgate Module) and start my diagnostics from there. No LGM showed up. A check of the wiring revealed no LGM on this vehicle and basically was old school from switch to wiper motor. With the rear liftgate open and the shop owner manipulating the rear wiper switch the interior lamps would come on or go out. That was my first clue where to go. Remember, phantom issues either resistive power shorts or bad grounds. I checked the ground at the wiper motor and depending on where the rear wiper switch was it was anywhere from 2.0v to 10.0v back to battery negative using voltage drop. Ok, we know we have a bad ground. The ground itself is behind the right rear interior panel. I really hate pulling panels when I do not have to. Lets check it at the liftgate connector that is easier.

I move this connector and my voltage drop fluctuates. Lets check the connector ends. I smell bad connection.

Here is one side of the connector.

The other side of the connector. Sorry, for the blurry pictures-you get the idea. Again, a substantial amount of current goes through here. Any loose connection, added resistance, etc will cause this. Terminal repair to the connector and this vehicle was back in action.

First up is a 2007 Cadillac Escalade EXT with climate control seat issues. This vehicle has both heated and cooled front seating with a mini blower motor for each seat. This is all controlled by the CCSM (Climate Control Seating Module) under the passenger front seat. I first became involved with this when the shop called asking me if I could program a new CCSM they were going to install in this vehicle for the problem of no operation of climate controlled seating. The dealer told the shop it needed to be programmed. Most GM modules do need to be programmed. A quick check of service information revealed this did not need programming it was "plug and play". I advised the shop of this and they installed the new CCSM and still had no climate control seat operation. That is where I came in. I first verified proper inputs to the CCSM with my Tech2 and also backprobed powers and grounds at the CCSM. All were good. Why wasn't it working?

Let's disconnect the connector and check for pin deformation, etc.

Well here we go. The main power feed terminal for the CCSM is smoked. I checked resistances of the seat heaters and blower motors from the disconnected connector. All were in specifications. I then amp drawed the circuits to check them dynamically and again all were good. A lot of current under the best of circumstances goes through this terminal. Better to be safe than sorry. A call to the dealer revealed they had this pigtail in stock-no suprise there, huh? A new pigtail was installed and we can now keep our butt warm in the winter and cool in the summer. How did we ever do without this?

Next up is a 2003 Toyota Sequoia that the battery would go dead overnight intermittently. The customer swears the headlamps turn on by themselves causing this. The shop has already installed a brand new battery and has never seen this phantom headlamp issue. I get called in and for the first couple of minutes of me manipulating switches and harnesses nothing happens. I turn my head and then look back and the headlamps are on and the switch is off and I have the keys in my hand. A second look and actually the DRL (Daytime Running Lamps) are on. DRL operation is controlled by the Body ECU. I hook up my Toyota Techstream scantool and I see no reason the Body ECU should be putting on the DRL lamps. I try to toggle the DRL relay on and off through the bi-directional functions of the scanner and they just stay on. Could the Body ECU be bad. Well, it is easy enough to disconnect. I do so and the lamps stay on. Do I have a stuck DRL relay? I don't think so since the vehicle should not have had the DRL lamps on to begin with key off. Hmm. Whenever I see phantom issues like this I think of two things-resistive shorts caused by moisture intrusion or bad grounds backfeeding. A quick voltage drop of ground circuits reveals excellent grounds. I am going for the resistive short. I start wiggling connections at the inerior fusebox which also serves as a junction box for many circuits including the DRL's and the lamps flicker. I trace the circuit to a particular connector at the fusebox. I cannot get this connector out of the fusebox. I have pliers on it and I do not want to break it off. I pull an adjacent connector at the fusebox and there are signs of moisture. There is green corrosion all over. I tell the shop owner he needs a fusebox. We finally get the connections out-here is the fusebox.

Taken on some water here for sure. A tech in the shop told me that this vehicle sees a decent amount of beach time in the summer months. Maybe, he got caught in the waves one time. Or, perhaps an old windshield leak. Here is another shot.

The moisture migrated into the fusebox and caused circuits internal to have continuity when they should not have. At first the shop owner asked me if we could save this fusebox. Not a chance!

This next one is from a body shop I service. It is a 2001 Ford Windstar with no rear lighting. Front lighting is operative. This vehicle uses a REM (Rear Electronics Module) to control the rear lighting. It is nestled over in the right rear of the vehicle behind a trim panel-see below.

I hook up my scantool to make sure it is communicating and getting proper inputs and to test the outputs. It is communicating and getting proper inputs. When I try to do output tests for the relays that control rear lighting via the REM-I hear nothing. A look at the diagram tells me that the relay command wire goes straight from the REM to the junction box under the left side of the dash. There are no connectors in between! So no divide and conquer mentality can be used here. To make matters worse the interior of this vehicle is fully intact. Usually, when I get a call from a body shop the interior is torn apart which makes it easier for me. This harness goes across the interior of the vehicle. So, I am thinking is a harness chafed on a seat anchor or rotted right in the middle of the truck. The nightmare scenario of taking this Windstar apart is gnawing at me. I know that the connections at the REM look good. I jump out the relay at the junction box and the rear lighting comes to life. So I know there is an issue at the control for the relay. Let's head for the junction box connector on the back that has the control circuit wire.

Well lookey here. I knew something was up when the connector was a bit of a pain to get out. Yes, water intrusion and Yes there should be four terminals on the top row and four terminals on the bottom. See what is missing?

There is the missing pin welded into the female terminal of the connector. This Windstar I believe has a windshield leak that started this ball rolling.

Finally, we have another fine GM vehicle. A 2006 Cadillac Escalade with complaints of no rear wiper and no rear defroster operation. I hooked up my Tech2 expecting to see a LGM (Liftgate Module) and start my diagnostics from there. No LGM showed up. A check of the wiring revealed no LGM on this vehicle and basically was old school from switch to wiper motor. With the rear liftgate open and the shop owner manipulating the rear wiper switch the interior lamps would come on or go out. That was my first clue where to go. Remember, phantom issues either resistive power shorts or bad grounds. I checked the ground at the wiper motor and depending on where the rear wiper switch was it was anywhere from 2.0v to 10.0v back to battery negative using voltage drop. Ok, we know we have a bad ground. The ground itself is behind the right rear interior panel. I really hate pulling panels when I do not have to. Lets check it at the liftgate connector that is easier.

I move this connector and my voltage drop fluctuates. Lets check the connector ends. I smell bad connection.

Here is one side of the connector.

The other side of the connector. Sorry, for the blurry pictures-you get the idea. Again, a substantial amount of current goes through here. Any loose connection, added resistance, etc will cause this. Terminal repair to the connector and this vehicle was back in action.

Sunday, February 19, 2012

2004 Jeep Grand Cherokee

Here is one 2004 Jeep Grand Cherokee with 88,656 miles on it. The issue here is no passenger side door functions such as power windows or power door locks. The other issue is no RKE (Remote Keyless Entry) functions as well from the key fobs. The drivers side operations work correctly. The Grand Cherokee platform is definitely one of the more popular vehicles I encounter. They have various issues both common and uncommon.

The shop has done some checking before I got there. Various panels have been removed in an effort to narrow down the search. The first thing that catches my eye is the aftermarket alarm module dangling. I am always wary of aftermarket alarms and their installations. I have seen many issues caused by either bad alarms or the installation. Let's have a look at the wiring diagram.

The system utilizes door modules in each door that communicate through a data buss called PCI ( Programmable Controller Interface) buss. It is very much like GM's Class 2 data buss. It is a peer to peer network meaning that any module on the network has the ability to communicate on it's own. Both the DDM ( Drivers door Module) and PDM ( Passenger Door Module) share a common power and ground feed as well. Looking through the service information I also come across this- I underlined the important tidbit of information.

The DDM and PDM each utilize integrated circuitry and information carried on the Programmable Communications Interface (PCI) data bus network along with many hard wired inputs to monitor many sensor and switch inputs throughout the vehicle. The PDM also receives inputs through an integral Radio Frequency (RF) Remote Keyless Entry (RKE) receiver. The DDM and PDM control and integrate many functions and features of the vehicle through both hard wired outputs and messages over the PCI data bus.

We also know that at least our source for power and source for ground is good since we have proper drivers side window and lock operation. So what is next?

This is what I do. I reach for my DRB3 and go into this menu. Factory tools do so many functions that the aftermarket tools may not have. I hit the enter button.

This is the next menu. What the DRB3 is going to do is look for any modules that are communicating on the PCI data buss and report. Such a great feature.

This is the first page. As you can see it is in acronym form so you have to know your Chrysler modules. Let's check out the next page.

Well we see a Driver Door Module but no Passenger Door Module. So, we know that the PDM is not reporting on the PCI buss. Let's get right to the PDM.

Pulling the passenger dise door panel gives me access to the PDM. I want to check power, ground, and whether it is receiving PCI buss messages. Lets first check for PCI data messages. I grab my scope and backprobe the PDM.

We have communication. Like I said just like Class 2 on a GM vehicle. We have a 7 volt square wave slightly off of ground to help with noise. So we know we dont have an issue with the PCI wiring to the PDM. Let's check power and ground.

This is the wire that is supposed to have battery voltage. We have a problem. Checking the ground wire at the PDM and that is good. So we have a power feed issue no doubt. But, is that all?

So, backprobed at the PDM I run a fused jumper from battery positive to the PDM. Lets rerun the PCI buss check.

Hello there PDM. I check passenger side window and lock operation and all is well. Now, it is time to find where the loss of voltage is. I know where I am going right away.

There it is a broken feed wire in the passenger side bellows between door and A pillar. Checking the other wires in the harness and they were all good. A quick repair of the wire and reassembly and all is well. The RKE worked like a charm as well. The shop owner was more than happy. This car was fixed with no parts and quickly. It is a bit unusual to see this sort of failure on the passenger side. I see it all the time on the drivers side however. Think about how many more times you open the drivers side versus the passenger side.

The shop has done some checking before I got there. Various panels have been removed in an effort to narrow down the search. The first thing that catches my eye is the aftermarket alarm module dangling. I am always wary of aftermarket alarms and their installations. I have seen many issues caused by either bad alarms or the installation. Let's have a look at the wiring diagram.

The system utilizes door modules in each door that communicate through a data buss called PCI ( Programmable Controller Interface) buss. It is very much like GM's Class 2 data buss. It is a peer to peer network meaning that any module on the network has the ability to communicate on it's own. Both the DDM ( Drivers door Module) and PDM ( Passenger Door Module) share a common power and ground feed as well. Looking through the service information I also come across this- I underlined the important tidbit of information.

The DDM and PDM each utilize integrated circuitry and information carried on the Programmable Communications Interface (PCI) data bus network along with many hard wired inputs to monitor many sensor and switch inputs throughout the vehicle. The PDM also receives inputs through an integral Radio Frequency (RF) Remote Keyless Entry (RKE) receiver. The DDM and PDM control and integrate many functions and features of the vehicle through both hard wired outputs and messages over the PCI data bus.

We also know that at least our source for power and source for ground is good since we have proper drivers side window and lock operation. So what is next?

This is what I do. I reach for my DRB3 and go into this menu. Factory tools do so many functions that the aftermarket tools may not have. I hit the enter button.

This is the next menu. What the DRB3 is going to do is look for any modules that are communicating on the PCI data buss and report. Such a great feature.

This is the first page. As you can see it is in acronym form so you have to know your Chrysler modules. Let's check out the next page.

Well we see a Driver Door Module but no Passenger Door Module. So, we know that the PDM is not reporting on the PCI buss. Let's get right to the PDM.

Pulling the passenger dise door panel gives me access to the PDM. I want to check power, ground, and whether it is receiving PCI buss messages. Lets first check for PCI data messages. I grab my scope and backprobe the PDM.

We have communication. Like I said just like Class 2 on a GM vehicle. We have a 7 volt square wave slightly off of ground to help with noise. So we know we dont have an issue with the PCI wiring to the PDM. Let's check power and ground.

This is the wire that is supposed to have battery voltage. We have a problem. Checking the ground wire at the PDM and that is good. So we have a power feed issue no doubt. But, is that all?

So, backprobed at the PDM I run a fused jumper from battery positive to the PDM. Lets rerun the PCI buss check.

Hello there PDM. I check passenger side window and lock operation and all is well. Now, it is time to find where the loss of voltage is. I know where I am going right away.

There it is a broken feed wire in the passenger side bellows between door and A pillar. Checking the other wires in the harness and they were all good. A quick repair of the wire and reassembly and all is well. The RKE worked like a charm as well. The shop owner was more than happy. This car was fixed with no parts and quickly. It is a bit unusual to see this sort of failure on the passenger side. I see it all the time on the drivers side however. Think about how many more times you open the drivers side versus the passenger side.

Subscribe to:

Posts (Atom)