This blog will explore the world of automotive diagnostics. We will show a new case study every week.I will also offer my opinions on various issues in the automotive world.

Sunday, September 21, 2014

Safe and Sound

This 2014 Chevrolet Cruze with 3,134 miles was in a recent collision event. The body shop did a great job of putting humpty dumpty back together again. Part of the repair was the replacement of the SDM (Sensing and Diagnostic Module) for the airbags as well as several other airbag related items. On many late model GM products the SDM comes blank and needs to be programmed and a setup procedure completed before the airbag lamp goes out and the vehicle can be returned to the customer. This is where I come in. Now I always tell the body shop on GM products that they have to have all the bad components replaced and a brand new GM SDM needs to be installed. The reason for all the faulty component replacement is because the SDM will not finish the setup procedure if there are any

faulty components such as open connections, blown out pre tensioners, etc. The reason for the GM module is simple. There are many outfits that claim that they can rewrite crash data on a SDM and then it can be reused. I personally don't agree with this and have always have had issues when trying to setup these modules. The normal price for a GM SDM is typically not that expensive why waste your time. So lets get the show on the road.

So the first step is to program the SDM. This will program the proper software into the module for this particular vehicle it is VIN driven. I hook up my laptop and use my GM MDI for an interface. I also attached my Midtronics battery maintainer and checked for proper voltage for programming. Using GM SPS I program the new SDM with the proper calibration. The screen above is just confirmation of a successful programming event. There are also valuable instructions in the smaller box. Basically, it says you must now run the Setup SDM application successfully for the module programming to be complete. I run the Setup SDM application which is a two part procedure. The first part marries the new SDM to the vehicles BCM. This procedure is called Setup Primary Key in BCM which it completed successfully. The next part is to Enable Deployment Loops. This vehicle failed to run this application successfully. I knew it wasn't going to be successful because the airbag lamp after programming the SDM was on solid. It should be flashing. Ok, the body shop must have missed something. This happens all the time when a part doesn't get installed or a connector is not attached properly.

This vehicle is a Global Architecture vehicle so a Tech2 will have limited to no data. Instead the factory tool here is GDS2. It is a software you lease from GM TIS. I run it though my GM MDI as this is the true blue factory way. There are other interfaces that work quite well with GDS2 as well. GDS2 is not as intuitive as the TECH2 and does take some getting used to. Lets check for some codes in the airbag system.

Here is a few screens in. The modules are listed on the left. I choose the airbag module.

Here is the trouble code screen. It tells me the trouble code and subcode, description, and status. As you can see we have three current trouble codes. The configuration code is due to the SDM not completing the Setup procedure. Our issues are with the two other codes for passenger side seatbelt pretensioners. Lets get some data.

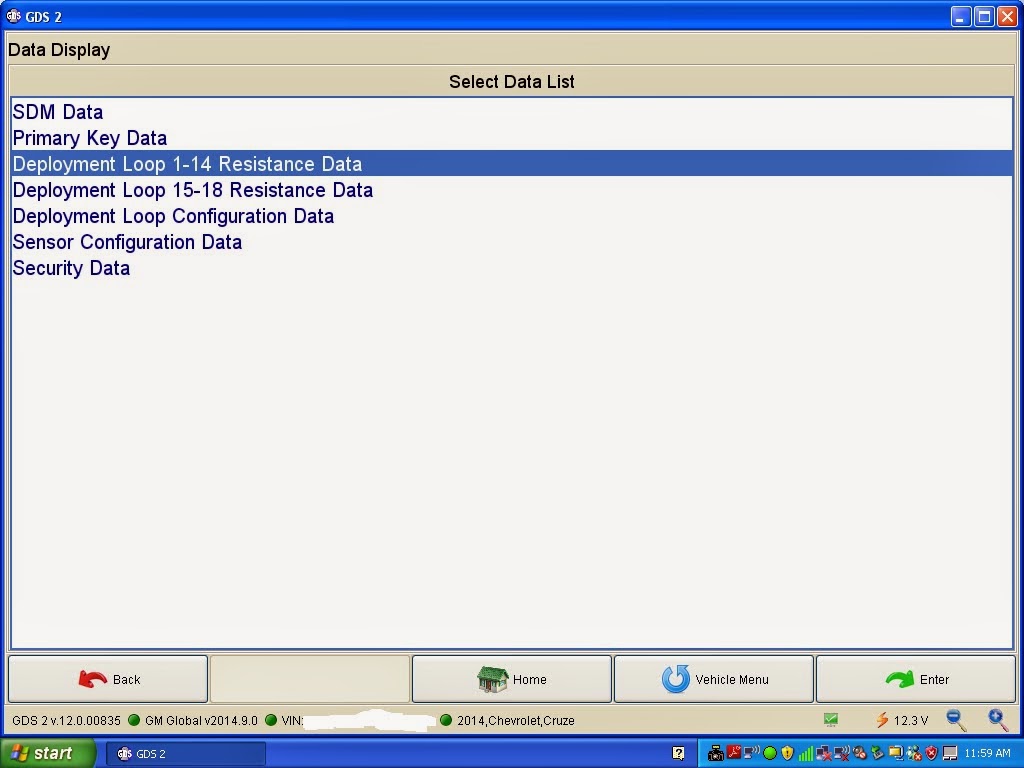

I head into the Module menu and choose Data Display.

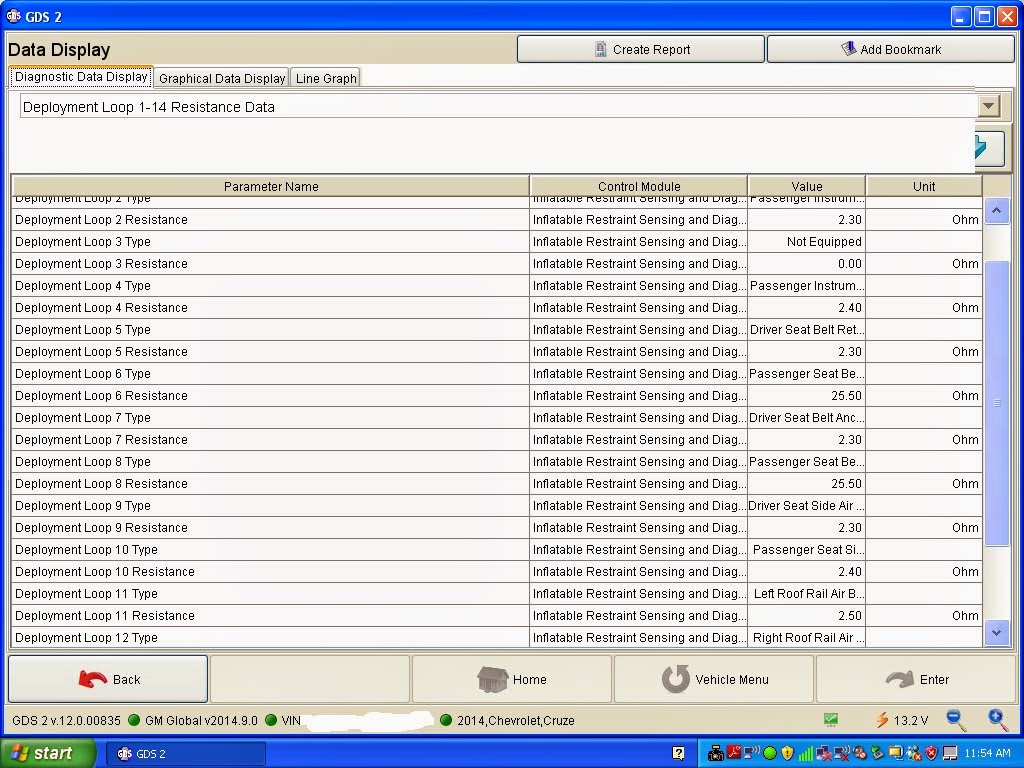

A wealth of information can be found in data now. Early GM systems had almost no useable scan data. Late model vehicles it is information overload. I choose Deployment Loop 1-14 Data. I am looking for something to smack me in the face.

There it is Loops 6 and 8 are different than the rest. The 25.50 ohms reading I see is typical of late model GM for a completely open circuit. Look at the other pids all typically between 2 to 3 ohms which is industry standard. Lets look at the items in question physically.

This is the drivers side seat belt seat pretensioner. This is how it should look-this is normal and our scan data supports this. Lets have a look at the passenger side.

A little different, right? When the vehicle was in the collision the SDM "blew" the pretensioner here and the belt sucked in to lock the occupant into the seat for safety. Ok, now I tell the shop owner we need more parts. I explain the issue and the fact that when he has all the parts correct the airbag lamp will flash. At that point I can come back and finish the Setup Procedure.

A couple of hours later I get a call from the shop. Parts are installed and airbag lamp is flashing. These are the old parts. One part is the aforementioned seatbelt pretensioner and the other is the B pillar belt assembly which also had a code for an open pretensioner. Remember, the codes.

Here is the after shot. Now, lets recheck that data.

Now, that's better. Time to run the Setup Procedure.

I choose the Configure New Module application in GDS2. It runs and completes. The airbag lamp goes out. Lets check for codes to be sure.

Success. I turn the key off and restart the vehicle making sure the airbag lamp goes through its normal cycle. I also check the PPS (Passenger Presence System) for proper operation. A recheck for codes and inform the shop owner we are good to deliver the vehicle.

Tuesday, September 9, 2014

Part 2..........

Our next mistaken identity vehicle is a 2005 Infiniti G35 coupe with 61,304 miles on it. Vehicle originally came in for state inspection with the MIL lamp on and many codes. The shop was able to correct many of the issues. They did however have a couple of codes that they could not rectify and the MIL lamp is still blaring away. In New York state if the MIL is on the vehicle will not pass its annual inspection. Ok, lets start by hooking up and seeing the codes and some data. Remember, to click or double click on pictures to make them bigger.

Here, I am using the Nissan Consult 3 scantool. I have a love/hate relationship with this scantool. I love this tool but it is glitchy and has a steep learning curve. It is not very intuitive. When you hook up it will do a VIN check and what is called a system call where it reaches out to see what modules are on the vehicle. The VIN function will be active on 2005 model years and up. It is retrieving the VIN information from the PCM/ECM. I notice something right away here. The VIN on the tool is not the vehicles VIN. I smell some swapped parts. Let's pull codes.

I pull some airbag codes. Yes, the airbag lamp is on and no it is not part of state inspection so the shop owner nor the vehicle owner is concerned about it. The ECM codes are what is putting on the MIL lamp. The P1564 will not illuminate the MIL. By the way ASCD stands for Automatic Speed Control Device in other words cruise control. Given the airbag codes presented it is a good bet this vehicle has a bad clockspring in the steering column.

Now on to the codes that are putting on the MIL. U1001 and U1000. These codes are very common on Nissan/Infiniti vehicles. In fact there is a TSB concerning these codes with certain Freeze Frame data to basically clean all the vehicle grounds. Including the ones on the interior dash support which requires taking half the vehicle apart. I check the Freeze Frame data and it does not match the criteria to clean all the grounds. CAN stands for Controller Area Network. This is a communication data buss that is very common in many vehicles. It is very fast and capable of supporting many modules quite easily. My experience is when I see these codes the module broadcasting these codes is not "seeing" a module that it should. The Consult 3 has a great tool for CAN diagnosis.

This function called CAN Diagnosis Support Monitor is one of the reasons I purchased this tool.

Here I am looking at what the ECM is seeing on the CAN line. OK means it is recognizing and Unknown means it doesn't see it. Looking at the data I can see that TCM (Transmission Control Module) is Unknown. This vehicle is a manual transmission vehicle. This would make sense because this manual transmission doesn't utilize a module. But wait....Something smacks me in the head.

I decide to look at the calibration in the ECM. I run this part number in the Infiniti programming database. By the way NASTF.org will have all the OE websites listed.

This calibration is for G35 coupe with an automatic transmission not a manual. Bingo. That is the reason behind the CAN codes. The ECM is looking for a TCM that is not there. Not seeing it sets the codes and puts on the MIL.

To confirm my theory I drop the ECM down. Which was hanging in by one nut and it has salvage yard writing on it. I advise the shop owner of my findings and tell him he has the option of a used ECM but it has to be the right calibration. A new ECM is pricey. He has to consult with the customer who has already spent a decent amount on this vehicle.

I get a call a couple of days later from the shop owner. A used one is nowhere to be found. A quality remanufactured ECM is not available as well. The customer decides to go new. This is a very pricey ECM. The first thing I do is run this number to see if the calibration is correct for this vehicle.

Looks like we have a winner. The next thing I do is plug it in and check the calibration through the Consult 3. Because, mistakes can happen in packaging.

Looking good. Now, we have to learn the NATS (Nissan Anti Theft System), write the VIN, clear codes, and run a IAVL (Idle Air Volume Learn) routine. Lets get started. But lets check codes first.

No more CAN codes. The P1564 code stays but will not affect MIL operation or prevent this vehicle from passing state inspection. Lets learn some anti theft.

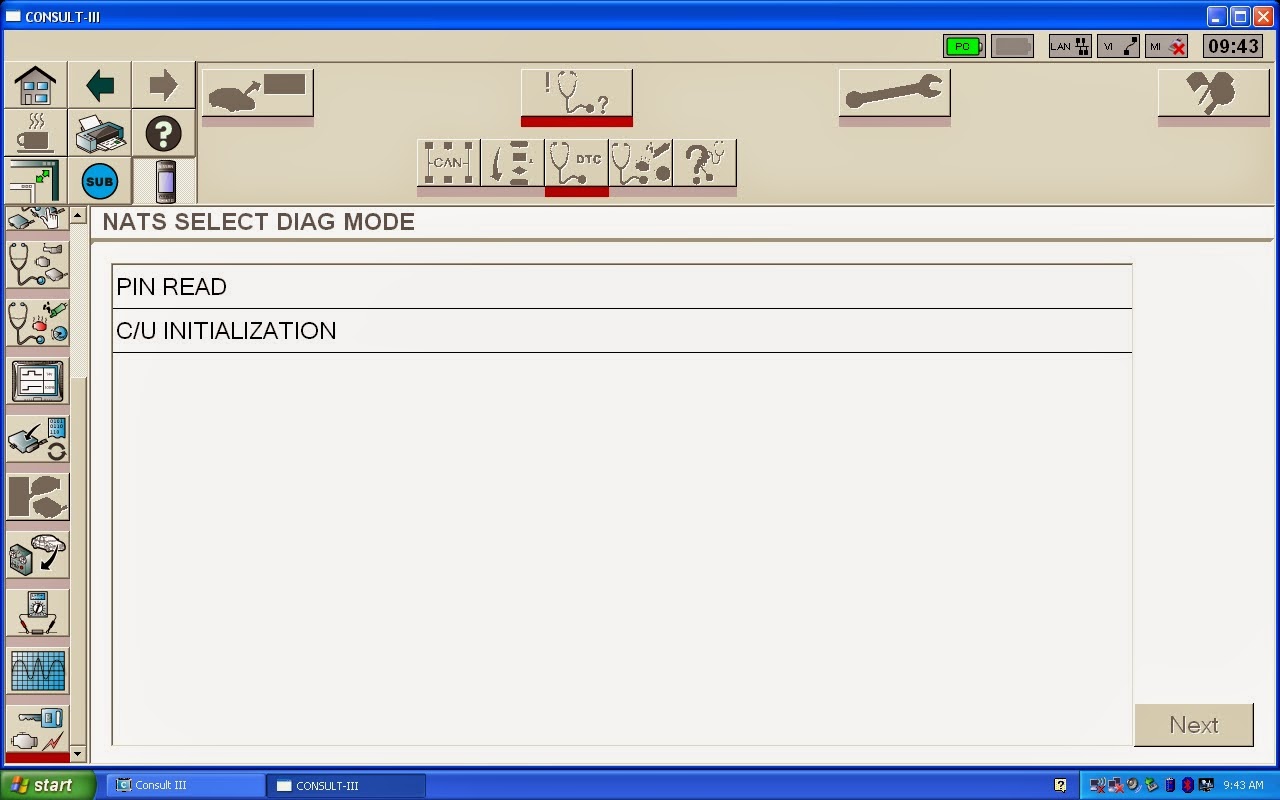

Since this vehicle was receiving a new ECM it is in a auto program mode. It will learn the key without any special procedures. If this was a used or remanufactured unit the following procedure would need to be done in order to learn the NATS. I included the procedure here. First step is to go into the NATS section of the Consult3. This NATS setup requires me to retrieve a 5 digit pin from the BCM then convert it into a 4 digit pin to perform initialization and learn keys. I retrieve the PIN using the PIN READ function.

Before I had this tool I would have to unearth the BCM and try to read the 5 digit PIN on a sticker on the BCM. Not so bad on an Altima or Maxima. Try a Quest. Anyway, now I have the 5 digit code. I use this 5 digit code into a Nissan converter that gives me a 4 digit PIN I can use.

I go into C/U (Control Unit) INITIALIZATION screen and input the 4 digit PIN.

Initialization is complete. But, we are not done yet. We have to actually learn the keys or keys. Consult your service manual for the logistics of this procedure. After we do this the vehicle starts and roars to life. Now we have to learn the VIN.

Using the WORK SUPPORT menu I choose VIN REGISTRATION. This procedure requires entering the VIN twice. I always use capitals.

I complete the procedure which includes a series of key offs and key ons. The next thing I do is close out the application and reboot the Consult 3. I want to see if it pulls the the correct VIN during system call.

Nice!!!!! Now we warm up the vehicle and perform the IAVL routine. Recheck for codes. I tell the shop owner the vehicle is ready to be driven to set emissions monitors. I recall the shop later that day and the shop owner informs me that the vehicle passed inspection no problems.

Tuesday, September 2, 2014

A Case of Mistaken Identity Part 1

Here is one 2001 Saturn L100 vehicle with 111,901 miles on it. The vehicle has been in a collision event and has had a host of "donor" parts installed. The car supposedly ran no problem before being shipped off to the body shop. The trouble at hand now is a start and stall situation. The funny thing is if the battery is disconnected and reconnected the vehicle will start and stay running. Just don't turn it off it will revert back to the start and stall situation. Various people have looked at the vehicle. It was determined that the BCM (Body Control Module) was bad. That is a fair assumption on this vehicle. I do a ton of BCM replacement/programming on Saturn vehicles. A used BCM was installed and still had the same issue. Well, this is where I tell the shop a used Saturn BCM is a definite no no. Saturn BCM's are VIN locked once programmed to a car they cannot be successfully reprogrammed to another vehicle. Yes, you can use them but you will issues such as airbags inoperative due to the VIN mismatch, accessories not working properly, and my favorite mileage change. I do a quick visual on the car and then check for codes.

I pull a U2105 and a U2106 out of the BCM. These are CAN (Controller Area Network) codes concerning module to module communications. Here are the codes and code set criteria.

Something is not sitting well with me at this point. Saturn is like the bastard child of GM. Take what you know about GM and throw it out when dealing with the Saturn platform. It keeps you on your toes for sure. I am looking at these codes and the code set criteria. Something is gnawing at me. I decide to look at some wiring.

I combined both the Saturn L100 2.2 Liter L61 wiring and the 2001 Saturn L300 3.0 Liter L81 wiring together. A couple of observations the L300 L81 utilizes a CAN network and a separate TCM (Transmission Control Module). The L100 L61 platform is pure Class 2 with no separate TCM. I had my first clue. I ask the shop for the replacement used BCM that he used.

No doubt this is a used unit. Junkyard writing galore. It finally hits me. I pop the original BCM out of the car to look at that.

Well they got the same one they had that is for sure. Hmmm it hits me....

They have V6 BCM's!!!!!!!! That is the reason for the CAN codes and the start and stall issue. I inform the shop who tells me how did this happen? I wish I knew. I tell him he needs a new BCM and I will program it for him. The next question is...... wait for it "Why can't I go with a used unit?" "I am losing my shirt on this car" "There is got be another reason"

After informing the shop I will have no part of a used unit he reluctantly agrees.

The new BCM arrives. Notice something different? I install and program the BCM. Relearn the theft deterrent and it start and stays running. Now he can concentrate on the other issues with this vehicle.

Monday, August 25, 2014

New Posts

Sorry gang I haven't posted in a long time. Fortunately, I have been very busy. I have been compiling some new case studies. I have some pet peeves about the industry that I want to write about as well. As always I welcome any input from you the readers. I do have to mention some people that help me remain sane in this crazy business. I will start with my good friend Joey Bag O Donuts he keeps me from going off the deep end and is without question one of the most intelligent human beings on the planet. My buddy that I walk a parallel life with Mike P from Ohio. Johnny from ABC who always comes up with some good stuff and keeps me thinking. Richie from Expert who always talks me up. Dave M. who always gives me an insight into academia and keeps me grounded. Jose J who is a great friend and thinks I should get into Mercedes and BMW-no way Jose. Lenny S who is a tribute to the industry always wanting to do the right job and ask questions. Mike B who is a brother in arms in this crazy automotive diagnostic game. Steven S who is just like me. Also, JT who is the without question the smartest guy in the automotive business. Oh yeah, my wife who puts up with all my bull$%#$ and has to deal with my OCD and the highs and lows of this business.

Sunday, March 2, 2014

Seeing Double Vision-Part 2

Here is a 2008 Dodge Nitro 3.7 Liter with 81,738 miles on it. Shop owner call me with a complaint of MIL on and O2 heater codes that come right back when erased. He is pretty sure it will need a PCM replacement. So sure that he has already ordered the replacement PCM. I told him I will do some quick checks before setting up the replacement PCM. So lets pull some codes.

Again, we are seeing all four oxygen sensor heater codes active. Lets look at some data.

Looking very familiar isn't it? We use the same testing procedures.

Here we actuated Bank 1 Sensor 1 oxygen sensor heater circuit with the WiTECH application at 25%. Again, I want to look at the command and amperage. We are flowing about 2 amps of current when activated. Lets look at static reading as well.

Same testing procedure as on the Jeep. We are checking resistance.

Here is the resistance of Bank 1 Sensor 1 oxygen sensor heater circuit-the whole circuit.

Here is the replacement PCM. Again, this is not a plug and play unit. Same procedures as Jeep.

Here I used the WiTECH application to program the replacement PCM.

The data after the PCM replacement. Now, are we to assume that whenever we get all O2 heater circuit codes at the same time that it is always the fault of the PCM? You better not. I try to treat each instance as brand new. If you don't you could make a wrong turn on your diagnostic path. Do the testing and confirm.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)