This blog will explore the world of automotive diagnostics. We will show a new case study every week.I will also offer my opinions on various issues in the automotive world.

Sunday, December 29, 2013

2000 Jeep Grand Cherokee

Here is a 2000 Jeep Grand Cherokee 111,087 miles with a 4.7 liter engine. This is actually at a transmission shop that got it from another shop. The vehicle sets a P1768 code for transmission control relay always off and the transmission goes into failsafe. The previous shop has tried a Transmission Control Module, Transmission Control relay, and a transmission solenoid pack. These vehicles are very common in my area and they have various issues. Lets look at the code and code set criteria.

Ok, so we have some code set and quite the number of possibilities. One item that is not listed is an issue with the solenoid pack or wiring. I have seen wiring down to the solenoid pack be frayed or shorted to power, ground, or another wire and set this code. Probably, what the other shop was thinking when they tried a solenoid pack. Lets look at the circuits involved for the Transmission Control relay.

So we have a regular 4 wire relay setup. Fused battery power comes into terminal #30 and when the relay is energized it flows out on terminal #87 to the TCM (watchdog circuit) and to the transmission solenoids. Remember this is a 4.7 liter. The control side of the relay is a constant ground from G104 to terminal #85 and the TCM powers terminal #86 to activate the relay. I put that in bold because most relay control circuits are ground activated. This is just the opposite. When the TCM wants to failsafe the transmission it discontinues the power to the relay and power is cut to the transmission solenoids and the transmission defaults to whatever failsafe gear it is engineered for. So how should I proceed? Remember, I have to work fast and efficiently. I need to know is the TCM turning off the relay? Is the relay really turning off? Are there other factors involved? I decide I am going to scope the relay output, relay control, and the relay ground for starters.

If you look on the diagram everything I want to see goes through two connectors C102 and C103. I am always very suspicious of Chrysler connectors and connectors in general. I don't like to just start disconnecting and inspecting connectors visually. The simple action of disconnecting and reconnecting can temporarily or permanently solve an issue. I backprobe whenever possible. Lets setup.

Here are the components labeled out. This is the right rear of engine compartment. Again, I am using Pomona backprobes available from Aeswave. They provide me with great confidence in testing with being minimally invasive. Let's go for a ride. I don't even get out of the driveway of the shop and the code sets and the transmission goes into failsafe. Lets look at the scope data.

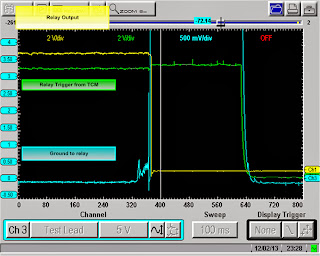

Now I can get a picture of what is going on. The first thing I notice is my ground to the relay is flipping out. The next is the TCM is not commanding the relay off. The relay output is dropping out. Lets zoom in on that moment.

There it is the ground is being lost and then the relay output is being lost. Look at my scaling for channel 3 (blue). A good ground in this type of circuit maybe 200mv at the most. I clear the code and repeat this a couple of times always with the same result. We are losing the ground. Lets go find this bad ground.

Why does this always happen to me? It seems like every time I need to find a ground or a connector it is a N/S. A no show or a not shown. Ok, we know it is right rear of engine. I follow the harness and it disappears down the back of the motor. It is tight. My guess it is attached to the bellhousing or back of the cylinder head. These vehicles get transmissions, cylinder heads, motor swaps, etc. So what can I do to make sure this will fix this elusive problem?

I run a jumper wire from battery negative to the wire that is supposed to be grounded by G104. I clear codes and road test. I left my scope attached and recorded.

Looks good to me. The transmission performed well. I figured I would also see how it is on the scanner as well.

Looking good. Switched battery and ignition feed voltages are right where they should be. No codes and like I said transmission performs well. I inform the transmission shop owner of my findings. I give him his options on repairing this vehicle. At this point the vehicle harness should be closely inspected and repaired/replaced.

Subscribe to:

Post Comments (Atom)

.JPG)

.JPG)

.JPG)

I'm from Poland, thank you very much.

ReplyDeleteCześć, mogę się z Tobą skontaktować ?

DeleteNapisz proszę na mojego maila jeżeli odczytasz wojtek.soloch@gmail.com

Delete