I am called to a shop this day for a problem with a 1997 Chrysler Sebring with a 2.5 liter V-6 motor. The shop owner explains to me that this vehicle has been all over the place. Lots of replacement parts. It runs real poor. So poor that the catalytic converter glows red after only a few moments of operation. The shop owner has had enough of this car. He has spent a considerable amount of time and resources on it. The vehicle sets Cam/Crank error codes as well. It has had multiple crank sensors. After listening to the shop owner and hearing the vehicle run. I am pretty sure we have some cam and crank relationship issue. I have been down the road with these vehicles before. There are many things that can go wrong from improper timing belt replacement, broken camshaft dowel pins, worn crankshaft gears, wrong or damaged flywheels, wrong year PCM with wrong flywheel with wrong camshaft sprocket, etc. The first thing I do is scope camshaft sensor and crankshaft sensor to look at the signals and more importantly the relationship between the two.

There she is. The crankshaft sensor reads off the flywheel and the camshaft sensor is inside the distributor which is driven off the end of the camshaft. The relationship between the two looks great. Amplitude of signals and ground point are also excellent. However, I am seeing a very weird crankshaft sensor pattern.

I changed the timebase so we can see more detail. Here the crankshaft sensor signal (arrows) is not what it is supposed to be. There should be four equal pulses reflecting the slots in the flywheel. If you look at the pattern sometimes we have this more often we have this freaky pattern. Hmmm. Do we have a damaged flywheel? This car has been around the block. Who knows how many times the transmission or engine has been out of this. Remember, this car has had multiple new crankshaft sensors. Something tells me that the problem still is with the crankshaft sensor itself rather than the flywheel. I recommend to the shop owner to get an OE crankshaft sensor and to make sure it has the felt spacer on the end of it. This felt spacer is the air gap adjustment between the sensor and flywheel. When installed it will bottom out. The first start takes the felt spacer off and sets the air gap. Subsequent crankshaft sensor removals and replacements require this felt spacer to be reinstalled before sending the sensor back home. I have seen plenty of aftermarket crankshaft sensors that do not posess this spacer. Installing the sensor without the spacer will cause certain sensor damage. I inform the shop owner of my hunch. But, warn him that he may be taking this transmission out. I reason with him that I would rather gamble with the sensor than a transmission removal. He agrees.

A couple of days later he calls me. He goes on to tell me that the vehicles crankshaft sensor he removed had obvious contact damage. The new OE sensor fixed the car and the car runs well. I was happy for him.

The next Chrysler is a 1995 Chrysler Cirrus with a 2.5 liter V-6 motor. It is a crank no start. Also, the shop owner says it has no scantool communication. I crank the car over. It has a nice even cranking sound. I hook up my scantool and I indeed have communication. This is one of those vehicles that have the familiar OBD2 data link connector but are really not true blue OBD2. We used to call these cars OBD one and a half on the techline. I check certain key parameters on the scanner such as map voltage, vehicle theft status, and cranking inj pulse. All look good. I check spark quality and scope ASD (Automatic Shutdown) relay voltage and injector pulse right at an injector. I have great spark, good ASD voltage cranking, and proper injector pattern. What gives? I spritz a little carb spray into the throttle body and car cranks starts and stalls. I break out the propane and can run the car. Ok, I know I have no fuel. Hooking a fuel pressure gauge up on this vehicle is a pain in the a$#. So, I use ATM (Actuator Test Mode) to actuate the fuel pump relay. I hear the relay click but no fuel pump operation. I remove the relay to jump out and look at the pattern with my low amp probe.

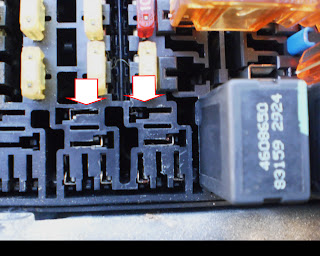

I removed the relay next to it for comparison. Do you see what is missing?

The terminal that is the output of the relay out to the fuel pump is not there. It has sunk down below where the relay blade terminals will make contact. I am able to use a long duckbill terminal to make contact with it to get this fuel pump to run. I hear the fuel pump turn on. I try to start and we still have a no start. Huh? The fuel pump is wailing away. Ok, lets get the low amp probe on there.

So we have a nice pattern. But very low amperage. I typically see 4-5 amps on these vehicles. Even a cheap pump will give me 3 or so. This is very low at barely 2 amps. Ok, we have a good pattern but low amperage. What would cause that? I think we are out of gas. A quick rap on the tank confirms this. I advise the shop owner to remove the underhood fusebox and repair the terminal. Oh yeah, put some gas in it as well.

This blog will explore the world of automotive diagnostics. We will show a new case study every week.I will also offer my opinions on various issues in the automotive world.

Saturday, August 27, 2011

Sunday, August 14, 2011

2007 Dodge Caliber

Yup, there she is. Straight from the body shop almost complete. It has an airbag lamp on and the body shop wanted to rectify this before putting the rest of the nose together. Smart move just in case there is a sensor or wiring that needs to be accessed. Let's pull some codes.

Ok, so we have some OCM (Occupant Classification Module) codes. Drivers seat track position sensor issue. Late model vehicles with "smart" airbags have information overload when it comes to keeping the occupants safe. So, where do I start? I know already. I look under the drivers seat and....

What do we have here? Yup, the sensor connector is swinging in the breeze. This day is going to be easy. I reconnect the connector. The CPA (Connector Position Assurance) lock tab was a little screwey. It needed to be gently "massaged" back into place. I moved the seat forward and back to make sure we don't have any issues with the sensor itself.

Here, is a shot of it from the backseat area connected. I cleared the codes and went on my way. This day is going to be easy. That was the mentality until I had to reindex a cam sensor on a 4.0 liter Ford Explorer and burned a half dollar sized portion of my forearm. The lesson here is KISS (Keep It Simple Stupid). Go after the obvious first. I just wish I followed my own advice all the time.

Ok, so we have some OCM (Occupant Classification Module) codes. Drivers seat track position sensor issue. Late model vehicles with "smart" airbags have information overload when it comes to keeping the occupants safe. So, where do I start? I know already. I look under the drivers seat and....

What do we have here? Yup, the sensor connector is swinging in the breeze. This day is going to be easy. I reconnect the connector. The CPA (Connector Position Assurance) lock tab was a little screwey. It needed to be gently "massaged" back into place. I moved the seat forward and back to make sure we don't have any issues with the sensor itself.

Here, is a shot of it from the backseat area connected. I cleared the codes and went on my way. This day is going to be easy. That was the mentality until I had to reindex a cam sensor on a 4.0 liter Ford Explorer and burned a half dollar sized portion of my forearm. The lesson here is KISS (Keep It Simple Stupid). Go after the obvious first. I just wish I followed my own advice all the time.

Ottotest Update

Well, I have now had the Ottotest for close to 6 months now. It has disappointed me more times than not. It is billed as an OE level tool. It does not even come close. The latest disappointment was a 1999 Hyundai Tiberon. The Ottotest didn't even have a menu for this car either using the vehicle or the VIN number. The tablet battery life is extremely short and it seems to struggle with the Nissan/Infiniti platform. There have been numerous updates. These updates typically are for 2010 model year coverage. I feel the tool and it's owners would be better served if they would concentrate on increasing the capabilities of the scanner on 2000-2008 model year vehicles. Case in point would be Ford automated evaporative test. Something, the Ford IDS scantool does that the Ottotest does not. I feel the tool is improving but it is at a snails pace. The typical updates always lists "client requested enhancements". Well tell me in detail what the enhancement is! I do use it more and more. I was recently checking an Infiniti I-30 for a shop and was showing him the graphing capabilities the Ottotest provides. The shop owner definitely liked what he was seeing. The Ottotest does do an excellent job of graphing. The speed of the tool needs to be increased tremendously. In the real world speed of a scanner from boot up to diagnosing is paramount. We technicians are not a patient group. I will keep you posted.

Subscribe to:

Comments (Atom)