This blog will explore the world of automotive diagnostics. We will show a new case study every week.I will also offer my opinions on various issues in the automotive world.

Sunday, February 15, 2015

Quick and Dirty

2005 Ford F-150 with 136,471 miles on it. This vehicle has the 5.4 Liter 3 valve engine with VCT (Variable Cam Timing). Shop owner tells me that that the customer is complaining of a rough idle and the Check Engine lamp on. This truck is super clean. I arrive at the shop and indeed it has a rough idle. Seems to improve with rpm. This is my first clue. The title here is "Quick and Dirty". I want the most information in the shortest amount of time.

I run a KOEO self test with my IDS. The vehicle has no on demand codes. But, has quite a few KOEO CMDTC's (Continuous Memory Diagnostic Trouble Codes) commonly referred to as memory codes and a pending code. Let's go through them. The P0012 is very common on these engines. I highlighted it for a reason. With IDS you get a decent code description. As you can see it is an issue with cam timing on bank 1. P0172 is bank 1 rich. P0174 is bank 2 lean. P0301 and P0303 are misfires detected for cylinders #1 and #3. P0316 is a misfire detected at start up. More clues here. But, let's look at some live data.

I load some pids I want to see on Datalogger on my IDS. I immediately see that bank 1 has issues. At an idle both banks should be near zero degrees for error and advance. Bank 2 is and Bank 1 is not.

Here is another truck I took a snapshot on that was running well. At this point I can also take a look at a couple of other great functions of IDS to get more information.

Here is a live power balance with IDS. Dark blue is where you are and grey is where you have been. It is called a histograph. Cylinder numbers in the vehicles firing order are up top and the green horizontal line represents 0. Below the zero line is a cylinder that is not contributing. The histograph shows cylinders 1, 2, 3, and 4 are below. Cylinders 5, 6, 7, and 8 are above. This is not uncommon to see cylinders following a misfiring rise above the zero line. On a good running vehicle the dark blue line is straight across the green zero line. So now I know that cylinders 1, 2, 3, and 4 are not contributing properly. From the layout of this engine these cylinders are all on Bank1 which is passenger side of the vehicle. I am starting to build my case. One more great test and I think I will be ready to present my case to the shop owner.

This is the relative compression test results. This function with IDS will compare cranking cylinder contribution and compare against each other. It is a great test. The test will automatically suspend injector pulse and prompt you to depress the accelerator pedal all the way down, and prompt you to crank the engine for 10 seconds. As you can see our problem cylinders 1, 2, 3, and 4 have low contribution compared to the others. I usually will investigate if its a 2% difference. We are looking at a much greater difference here. Sometimes, when there are cam timing codes this test can get altered or refuse to run. I did backup this finding with a cranking amperage scope test to confirm.

Here is vehicle that has no issues. Big difference. At this point I have a pretty good case with either a timing chain issue on bank 1 or a stuck phaser on bank 1. More likely bank 1 chain is off. I see this issue where the tensioner goes bad and leaks internally and doesn't provide proper tension on the chain or bank 1 timing chain guide broke and caused the chain to skip. The other issues that lead me here are the opposing fuel trim codes one side lean and the other side rich. Also, the fact that the misfire improved with rpm. All signatures for a mechanical valve timing issue. I present my case to the shop owner. I can pinpoint it further but would need additional time and diagnostic costs. He refuses at this point until he informs the customer. The customer was figuring on some plugs and coils was going to take care of this unfortunately not. I also discussed with the shop owner the oiling issues with this engine. I always advise my customers not to do any internal engine work on these engines until a thorough manual oil pressure test has been performed with the proper weight and amount of oil. Shops are always surprised when I tell them you need to have a minimum of 20psi hot in gear and the needle should be rock stable. If it does not meet this minimum reading or the needle is erratic the oiling system must be repaired first before repairing other issues. The whole VCT system revolves around proper oil pressure.

Sunday, February 8, 2015

Communication Breakdown

This 2008 Jeep Grand Cherokee with 68,592 miles on it has an issue. The shop owner called me saying that dash gauges, turn signals, power locks, and radio were all inoperative. Furthermore, the dash had every warning lamp illuminated. The vehicle started and ran quite well. I arrived at the shop and sure enough the complaints were verified. I have seen ignition switch issues cause this same set of circumstances before. I checked voltages at a couple of places and quickly ruled that out. It was time to dig deeper.

I hooked up my WiTech system and quickly saw that one whole communication data buss was inactive. The codes I pulled from the FCMCGW (Front Control Module Central Gateway) confirmed what I saw on the topology screen. I needed to check actual voltages on the CAN B buss.

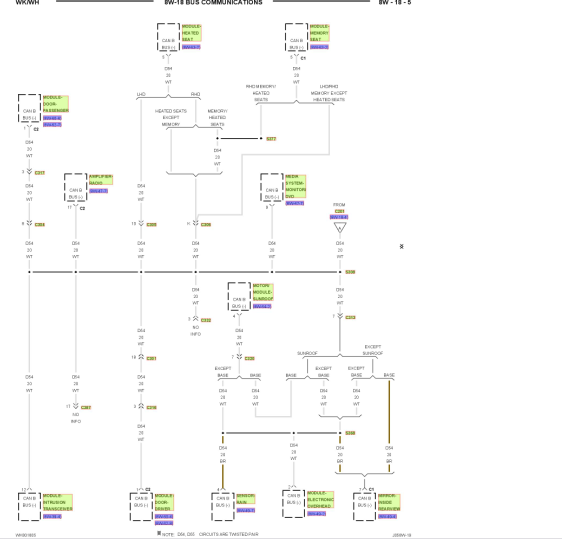

Here is a little network topology layout for this Jeep. Let's review operation. We will start at the FCMCGW. This is the central hub or gateway for both the CAN-C buss and the CAN-B buss. It also translates to a Diagnostic CAN-C buss to the Data Link Connector. Some earlier diagrams will show this as CAN-D for CAN Diagnostic. CAN-C modules are items that need high speed data transmissions for operation such as PCM, TCM, ORC (Airbag Module), etc. This data buss typically is not fault tolerant. In other words if we have a short to power, a short to ground, an open on one wire the buss will be compromised and will not function properly. CAN-B buss has slower speed data transmission and such has "non-essential" modules on its wiring. These include Drivers Door Module, Sunroof, Parking Aid, etc. This buss is fault tolerant. If one wire was open or shorted the modules would continue to operate. Fault codes would be set however. Both CAN-C and CAN-B are two wire twisted lead buss systems. Both buss systems "mix" at FCMCGW. I need to check CAN-B buss voltages. Hmmm, where to check.

My favorite spot and easiest on this platform is under the passenger front seat at the Heated Seat Module. I backprobe with my scope on both CAN-B buss wires at the HSM. I have absolutely no activity. I spared you the scopeshot. I also verified proper power and ground at the HSM. This can play an important factor as well into buss communication. Now, I am left with do I have a wiring issue or a module fault. I go back to my WiTech.

I go into the Loss of Comm Test. This shows all the modules that should be there and if they are reporting. As you can see all the CAN-C modules are reporting as well as the FCMCGW. All of the CAN-B modules are not reporting and more importantly they all have the same number of no responses. I leave my scope leads in at the HSM and disconnect the connector and cycle the key. Still no activity on the buss. I always try the easiest action first. So I know that my HSM is not my issue. I have a communication breakdown. There is a reason I named this post communication breakdown. It is one of my favorite Led Zeppelin songs. When I find myself getting scattered I can always count on the music of Led Zeppelin to get my on track again. So, I go back to my truck get some Zeppelin on and look at a wiring diagram for the CAN-B buss system.

Here is one leg of CAN-B. Something is corrupting the CAN-B buss. That is a lot of modules to disconnect one at a time or wiring to check. I close my eyes and let the voice of Robert Plant carry me away to even me out. What do I always say and preach? Break it down or divide and conquer. I look at the wiring diagram looking for my best course of action. What will give me the best results.

As Jimmy Page belts out yet another one of his signature flawless riffs it comes to me. This C313 will give me possibly four modules if I disconnect it. Ok, now lets look where it is. Service information says it is located left rear of vehicle behind an interior panel. Great. One thing the liftgate is inoperative. Yes, I could pop that panel off and manually unlock it but that is more work. I crawl over the seats and was able to get to the left rear interior panel that hides C313.

I pry it back a bit to uncover C313. I disconnect it and the horn starts going off. Bingo! I jump back out. Hit the remote to shut off the blaring horn and cycle the key.

I am now able to open the liftgate. Here is that panel as viewed from the open liftgate area. My scope reading at the HSM show activity. I go back to the Loss of Comm Test.

Here it is after disconnecting C313. Now, the only non reporting modules are the Sunroof and the EOM (Overhead Console). All functions are restored save the Sunroof and EOM. I inform the shop owner that further diagnostics would require dropping the headliner to disconnect said modules and inspect wiring to the modules. I am leaning heavy to a bad Sunroof module. The shop owner then tells me that last summer this vehicle had issues with sunroof drains clogging. At this point the shop owner also advises me to leave C313 disconnected until he asks the customer if they want to go further. Apparently, the customer just called and their other vehicle broke down that morning and they are without a vehicle and need a vehicle desperately. I pull out of the shop with the sounds of Led Zeppelin pouring through my speakers. Hey Hey What Can I Do.

Sunday, February 1, 2015

Mailbag

I get quite a few private emails asking for advice or problems concerning a vehicle. Rather than answering them privately I will answer them online so we can all benefit. I will display the email in full as it was sent but I will not disclose the senders email address. Just in case they want to be anonymous. Please realize I get email from all over the world so sometimes spelling and sentence structure may not be perfect. Cut them some slack. Here are a few. My answer will be in blue writing.

Hi i am a technician that reads your blog with great anticipation , i recently had a 05 max semuler to your 06 maxima you covered in your 2015 January blog came into the shop running and then would not start for nothing with the same symptoms . Customer would not go no further with the reapers or diagnostics but i feel pretty sure it was the seem problem . You make it look so easy , if you had to choose between diagnostic equipment , training , information what would you chose why and in what order and thank you so very much looking forward to the next one , just wondering have you considered videos sometimes and thanks again you are the man .

Thank you for reading. I really enjoy getting feedback from the people who read it. Believe me it is not easy. You see after it has been processed and written up. Plus, after the repair has been made it always looks easy and logical. I get my butt kicked just like every other tech. I always look at it as a learning experience. Even though when I am in the heat of the moment I don't think that way.

On to your question about choices. I would not be able to choose between the three. They intertwine and are dependent on each other. You need diagnostic equipment. But, you also need training to use the equipment to it's full potential. You definitely need accurate current information to repair vehicles today. There is so much that you can't memorize information. I think a blend of the three along with dedication by the technician equals a successful career. You have to be willing to put in the time to excel in this industry. You have to ask "Why did that happen?" instead of "I don't care".

I have considered videos. Anyone that knows me will tell you I am better in real life. I am a very animated and demonstrative person. Maybe, I will have to start my video career. As far as me being the man. Thank you. But, I am just one of many dedicated, intelligent, and caring technicians in this industry. There are many "Men" and some "Women" as well.

Am an automobile technician. I have a 2000 Pathfinder that won't start. There's spark on the plugs and there's good pressure on the fuel pump. I scanned it and got the P1320 code. Pls what do I do?

Well this can go many ways here. Let's start with the P1320 code. The P1320 in it's self usually doesn't cause a no start. Now let' examine your testing. You say you have spark. How are we measuring that? Are you using a scope? Screwdriver? I would recommend what I call my $14.00 scope. This is an adjustable spark tester that you unscrew to create an air gap. Not a bulb type tester. They are on any tool truck. Get one and unscrew it out to 30KV which is approximately 3/4 of an inch. Now do we have bright white consistent spark while cranking? Then we have to talk about whether we are getting spark at the proper time. That can get a little involved. Many methods from simple to hi tech.

Good pressure on the pump. What was the pressure? Did we use a gauge? Or did we use the calculation of how far the fuel shot out in feet to pressure calculation? I am kidding on that last one. Where did we put the gauge? In place of the fuel filter, inline or "deadheaded" on the end of the pressure line. This placement will make a big difference. But, hey lets make it simple and fast. If we spray some good quality carburetor spray in the throttle body and crank it over does it kick? Want to start? Or nothing? Are the plugs coming out wet or dry?

Was there any recent work done to the vehicle. When was the last time the vehicle started? Is the fuel stale? Injectors glazed over from rotten fuel? What kind of tooling do we have at our disposal? These are all factors to consider. Start with spark quality and then see if it wants to kick on carburetor spray. Keep us posted and I am sure we can get your Pathfinder rolling again or give it a proper burial.

Hi i am a technician that reads your blog with great anticipation , i recently had a 05 max semuler to your 06 maxima you covered in your 2015 January blog came into the shop running and then would not start for nothing with the same symptoms . Customer would not go no further with the reapers or diagnostics but i feel pretty sure it was the seem problem . You make it look so easy , if you had to choose between diagnostic equipment , training , information what would you chose why and in what order and thank you so very much looking forward to the next one , just wondering have you considered videos sometimes and thanks again you are the man .

Thank you for reading. I really enjoy getting feedback from the people who read it. Believe me it is not easy. You see after it has been processed and written up. Plus, after the repair has been made it always looks easy and logical. I get my butt kicked just like every other tech. I always look at it as a learning experience. Even though when I am in the heat of the moment I don't think that way.

On to your question about choices. I would not be able to choose between the three. They intertwine and are dependent on each other. You need diagnostic equipment. But, you also need training to use the equipment to it's full potential. You definitely need accurate current information to repair vehicles today. There is so much that you can't memorize information. I think a blend of the three along with dedication by the technician equals a successful career. You have to be willing to put in the time to excel in this industry. You have to ask "Why did that happen?" instead of "I don't care".

I have considered videos. Anyone that knows me will tell you I am better in real life. I am a very animated and demonstrative person. Maybe, I will have to start my video career. As far as me being the man. Thank you. But, I am just one of many dedicated, intelligent, and caring technicians in this industry. There are many "Men" and some "Women" as well.

Am an automobile technician. I have a 2000 Pathfinder that won't start. There's spark on the plugs and there's good pressure on the fuel pump. I scanned it and got the P1320 code. Pls what do I do?

Well this can go many ways here. Let's start with the P1320 code. The P1320 in it's self usually doesn't cause a no start. Now let' examine your testing. You say you have spark. How are we measuring that? Are you using a scope? Screwdriver? I would recommend what I call my $14.00 scope. This is an adjustable spark tester that you unscrew to create an air gap. Not a bulb type tester. They are on any tool truck. Get one and unscrew it out to 30KV which is approximately 3/4 of an inch. Now do we have bright white consistent spark while cranking? Then we have to talk about whether we are getting spark at the proper time. That can get a little involved. Many methods from simple to hi tech.

Good pressure on the pump. What was the pressure? Did we use a gauge? Or did we use the calculation of how far the fuel shot out in feet to pressure calculation? I am kidding on that last one. Where did we put the gauge? In place of the fuel filter, inline or "deadheaded" on the end of the pressure line. This placement will make a big difference. But, hey lets make it simple and fast. If we spray some good quality carburetor spray in the throttle body and crank it over does it kick? Want to start? Or nothing? Are the plugs coming out wet or dry?

Was there any recent work done to the vehicle. When was the last time the vehicle started? Is the fuel stale? Injectors glazed over from rotten fuel? What kind of tooling do we have at our disposal? These are all factors to consider. Start with spark quality and then see if it wants to kick on carburetor spray. Keep us posted and I am sure we can get your Pathfinder rolling again or give it a proper burial.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)